In the dynamic landscape of Malaysia’s motor industry, precision stands as a cornerstone for achieving unparalleled engine performance. Among the various techniques contributing to this precision, cylinder metal honing takes centre stage.

This article explores the art of cylinder honing and the transformative impact it has on crafting high-performance engines, emphasizing the vital role it plays in the ever-evolving motor sector. It delves into the technical nuances of honing techniques, showcasing how precision and expertise contribute to superior engine efficiency and longevity.

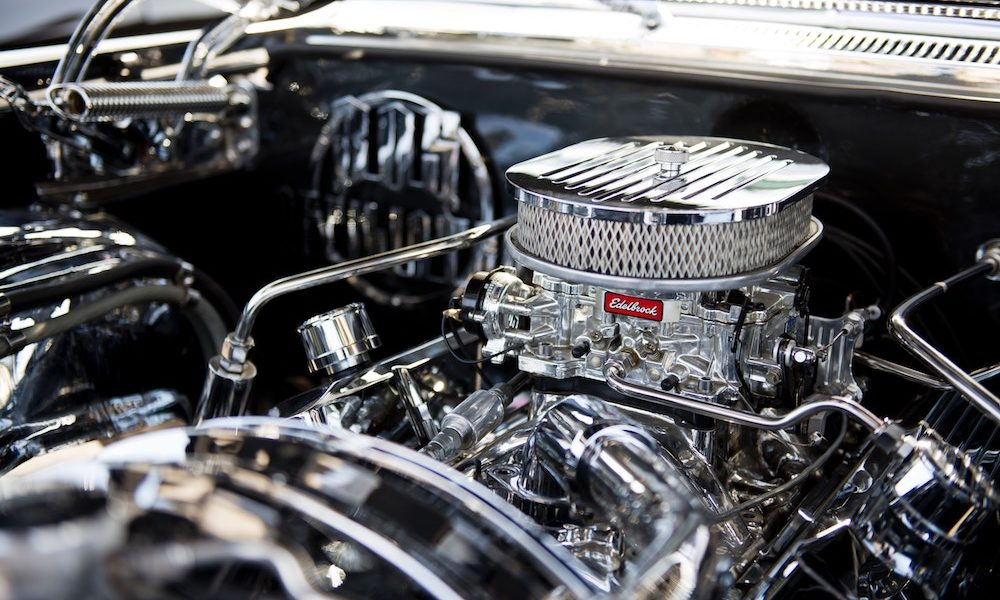

Crafting High-Performance Engines through Cylinder Honing

In the heart of Malaysia’s motor manufacturing hub, the meticulous craft of cylinder honing takes engines to new heights. Precision is not merely a requirement; it’s an art form that ensures engines function optimally and endure the rigours of demanding applications. The process of machine honing, coupled with the integration of hard chrome, reinforces the strength and resilience of vital engine components.

Cylinder honing, with a focus on hard chrome application, enhances the surface integrity of engine cylinders. This meticulous process not only ensures a smooth and consistent bore but also contributes to improved wear resistance, resulting in engines that withstand the test of time. In the realm of Malaysia’s motor industry, where efficiency and durability are paramount, the art of cylinder honing sets a new standard. Discover more here!

Unveiling the Secrets of Chroming Plating for Motor Components

As engines evolve, so do the demands on the components that power them. Chroming plating emerges as a crucial technique in enhancing the durability and wear resistance of motor components.

Hard chrome, known for its exceptional hardness and corrosion resistance, becomes a key player in this process. The application of industrial hard chroming plating involves depositing a layer of hard chrome onto the surface of essential engine parts, creating a shield against abrasion and environmental stressors.

This transformative approach not only prolongs the lifespan of motor components but also ensures consistent performance under challenging conditions. Malaysia’s motor sector embraces the secrets of chroming plating to fortify engines, making them capable of delivering optimal performance across diverse applications.

Metal Marvels: Enhancing Motor Components with Thermal Spray Coating

In the pursuit of excellence, the motor industry in Malaysia turns to thermal spray metal coating as a revolutionary solution. This advanced technique involves applying a fine mist of metal onto engine components, creating a protective layer that enhances resistance to wear, corrosion, and thermal stress.

The precision offered by hvof thermal spray coating complements the earlier stages of machine honing and chroming plating, providing a comprehensive solution for elevating motor components to new heights.

Thermal spray coating stands as a testament to innovation in Malaysia’s motor sector. By integrating this technology, manufacturers ensure that engines not only meet but exceed the performance expectations of a rapidly evolving industry.

Elevating Engine Efficiency: The Future of Motor Manufacturing in Malaysia

As the wheels of progress turn, the amalgamation of machine honing, chroming plating, and thermal spray coating shapes the future of motor manufacturing in Malaysia. Precision-driven technologies redefine the standards for engine efficiency, setting the stage for a new era in the motor industry.

In the pursuit of crafting high-performance engines, Malaysia’s motor sector embraces these metal marvels, recognizing their indispensable role in achieving a future where engines are not just powerful but resilient. The integration of hard chrome and metal spray coating propels the motor industry towards unparalleled excellence.